1. Introduction

In a world constantly seeking smarter, smaller, and more efficient solutions, the Peltier module—also known as a thermoelectric cooler—has long captured the imagination of engineers, DIY hobbyists, and researchers alike.

Its ability to generate a cooling effect with no moving parts, purely by running electricity through a semiconductor, seems almost magical.

But beneath this futuristic promise lies a harsh reality of low efficiency, high energy consumption, and challenging heat management that often turns practical projects into cautionary tales.

This blog post is an attempt to unveil everything you should know about Peltier modules: how they work, when they shine, when they fail, and how to truly benefit from them—or decide not to use them at all.

2. What is a Peltier Module?

A Peltier module (also called a thermoelectric cooler or TEC) is a solid-state active heat pump that transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current.

It essentially acts like a “reverse heater.”

Instead of generating heat, it moves heat away from an object to cool it down.

At its core, the module is made up of semiconductor materials sandwiched between two ceramic plates. When electric current passes through the module, one side gets cold and the other gets hot.

Peltier modules are named after the Peltier Effect, discovered by Jean Charles Athanase Peltier in 1834.

3. How Peltier Modules Work

Understanding the working principle involves two main effects:

- Seebeck Effect: When two dissimilar metals are joined at two points, and one junction is heated, a voltage is generated.

- Peltier Effect: When a current passes through two dissimilar materials, heat is absorbed or released at the junctions.

Working Principle in Detail

- A typical Peltier device uses n-type and p-type semiconductor materials.

- N-type (negatively charged) semiconductors have extra electrons.

- P-type (positively charged) semiconductors have electron holes.

- When powered, electrons and holes move, absorbing heat on one side (making it cold) and releasing heat on the other side (making it hot).

Thus, with continuous current, a constant temperature difference is maintained between two surfaces.

4. Types of Peltier Modules

- Single-Stage Modules

- Simple, one set of p-n junctions

- Best for moderate cooling (<70°C temperature difference)

- Multi-Stage Modules

- Multiple modules stacked for higher temperature differences (>70°C)

- Used in laser cooling, deep cryogenics

- Custom Modules

- Built specifically for special applications like infrared detectors, space missions

5. Applications of Peltier Modules

✅ Electronics Cooling

- CPUs, GPUs, Sensors, Laser Diodes

✅ Portable Refrigeration

- Mini-fridges, wine coolers, travel coolers

✅ Medical Devices

- Insulin coolers, DNA preservation

✅ Space Applications

- Cooling infrared sensors on satellites

✅ DIY Projects

- Making custom water chillers, CPU coolers

✅ Military & Defense

- Thermal imaging sensors, night vision cooling

6. Advantages of Peltier Modules

✨ Solid-State Operation: No moving parts, no noise.

✨ Compact and Lightweight: Can fit into small spaces.

✨ Bidirectional Heating/Cooling: Simply reverse the polarity.

✨ Precise Temperature Control: Fine-tune cooling with current adjustments.

✨ Durability: If operated within limits, they last long.

✨ Eco-Friendly: No refrigerants like CFCs that harm the ozone layer.

7. Disadvantages of Peltier Modules

⚡ Poor Energy Efficiency: Coefficient of performance (COP) is very low compared to vapor compression systems.

⚡ Heat Dissipation Challenge: Needs large heatsinks or water cooling.

⚡ High Power Consumption: Consumes a lot of current for small cooling effect.

⚡ Limited Cooling Capacity: Only good for low-to-moderate cooling loads.

⚡ Risk of Overheating: Without active heat removal, they overheat quickly.

⚡ Condensation Risk: Cold side can go below dew point causing water droplets (bad for electronics).

8. Real-World Experiment and Observations

🔍 In a real-world setup:

- Input: 12V @ 8A → 96 Watts (~100W)

- Result:

- Hot side: 50–60°C

- Cold side: 10–20°C

- Problems Encountered:

- Huge heating on the hot side

- Cooling effect limited

- Required massive water-cooling or huge heatsinks

- Setup became bulky and energy-intensive

- Financially not feasible

Conclusion:

Without very effective and active cooling (especially of the hot side), Peltier modules fail to achieve usable cooling for larger systems.

9. Efficiency and Technical Limitations

- Coefficient of Performance (COP): Often <1 (terrible compared to compressor fridges with COPs of 2–4).

- Thermal Resistance: Heat generated internally resists cooling efficiency.

- Ambient Conditions: Hotter environments worsen performance.

- Module Wear-Out: Cycles of heating and cooling reduce module life.

10. Financial and Power Consumption Analysis

| Factor | Peltier Setup | Traditional Refrigerator |

|---|---|---|

| Initial Cost | Medium | Medium |

| Power Consumption | Very High | Moderate |

| Long-Term Cost | Very High (electricity bills) | Low |

| Space Required | High | Low |

| Maintenance | Low | Moderate |

🔴 Profit/Loss Analysis:

Using Peltier for continuous cooling is generally a loss unless in niche or small-scale cases (e.g., cooling a tiny sensor).

11. Alternatives to Peltier Modules

- Vapor Compression Systems: Refrigerators, air conditioners

- Heat Pipes: Laptops, smartphones

- Vapor Chambers: High-performance electronics

- Phase Change Cooling: Gaming PCs

- Passive Cooling (Natural Convection): Solar-powered devices

12. When Should You Use a Peltier Module?

👍 Low-power sensor cooling

👍 Portable mini-coolers

👍 Short-term, temporary cooling

👍 Educational demos and experiments

👍 When solid-state, silent cooling is required

13. When Should You Avoid Peltier Modules?

👎 Continuous high-load cooling

👎 Power-critical applications (e.g., battery devices)

👎 Space-constrained projects

👎 Cost-sensitive applications

14. Future of Thermoelectric Cooling

🔮 Research is happening on:

- New materials with higher ZT (figure of merit)

- Flexible thermoelectric materials

- Waste heat recovery

- Thermoelectric generators (TEG) for IoT devices

Possible future: Peltier-like materials integrated into building structures or wearables.

15. Design Tips and Best Practices

✅ Always use proper heatsinks/fans

✅ Apply thermal paste

✅ Maintain input voltage regulation

✅ Insulate the cold side to avoid condensation

✅ Avoid physical shock to the module

16. Building a Peltier-Based Cooler (DIY Section)

- Gather: TEC module, heatsink, fan, thermal paste, DC power source

- Attach heatsink to hot side

- Attach cooling plate to cold side

- Apply thermal paste for better conduction

- Use insulation to improve efficiency

- Power it up and measure temperature drops

Optional: Add a water cooling loop for heavy-duty cooling!

17. Peltier Module in Renewable Energy Context

- 🔥 Waste heat recovery (TEG modules)

- ☀️ Solar-powered thermoelectric cooling (remote areas)

- 🔋 Battery charging from temperature differences

Still in early stages but very promising!

18. Case Studies

- NASA uses Peltier modules to cool infrared detectors.

- Portable vaccine carriers use Peltier cooling in remote areas.

- DIY enthusiasts use it for custom mini-fridges or PC cooling.

19. Environmental Impact

♻️ Positive:

- No harmful refrigerants

- Potential for renewable integration

⚠️ Negative:

- High power draw = higher carbon footprint if electricity is non-renewable

- Recycling Peltier modules is complicated

20. Pros and Cons Summary Table

| Pros | Cons |

|---|---|

| Compact | Poor efficiency |

| No moving parts | High electricity consumption |

| Silent operation | Complex cooling setup required |

| Durable | Limited cooling power |

| Eco-friendly | Expensive for large systems |

21. Final Thoughts

- Peltier modules are fantastic educational tools and suitable for small-scale or temporary cooling needs.

- Not suitable for heavy-duty or large cooling requirements.

- Great learning experience for engineers, students, and innovators.

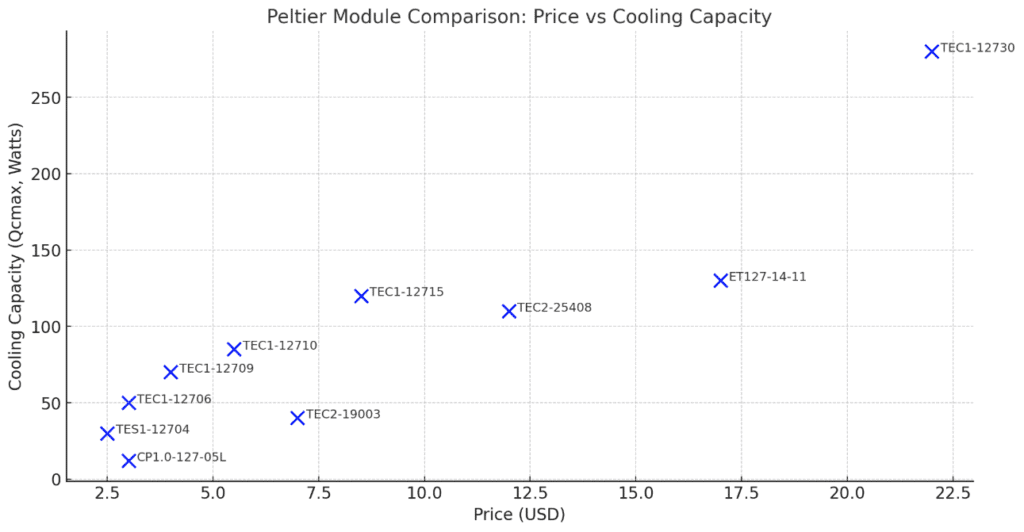

A detailed table of different popular Peltier models, with their specifications and price:

- Model Name

- Dimensions

- Voltage (V)

- Current (A)

- Maximum Temperature Difference (ΔTmax)

- Maximum Power (W)

- Cooling Capacity (Qcmax)

- Approximate Price (in USD)

Here’s a professional-style table:

📊 Popular Peltier Modules – Specifications and Pricing

| Model | Dimensions (mm) | Voltage (V) | Current (A) | ΔTmax (°C) | Max Power (W) | Cooling Capacity (Qcmax) | Approx. Price (USD) |

|---|---|---|---|---|---|---|---|

| TEC1-12706 | 40 × 40 × 3.6 | 12V | 6A | 65°C | 72W | ~50W | $2 – $4 |

| TEC1-12709 | 40 × 40 × 3.6 | 12V | 9A | 65°C | 108W | ~70W | $3 – $5 |

| TEC1-12710 | 40 × 40 × 3.8 | 12V | 10A | 65°C | 120W | ~85W | $4 – $7 |

| TEC1-12715 | 40 × 40 × 4.0 | 15V | 15A | 68°C | 225W | ~120W | $7 – $10 |

| TEC1-12730 | 62 × 62 × 4.5 | 15V | 30A | 65°C | 450W | ~280W | $18 – $25 |

| TEC2-25408 | 50 × 50 × 4.0 | 24V | 8A | 67°C | 192W | ~110W | $10 – $15 |

| TEC2-19003 | 40 × 40 × 3.8 | 24V | 3A | 65°C | 72W | ~40W | $6 – $8 |

| TEG1-1263-3.4 | 40 × 40 × 3.3 | 6V (Generator Type) | 3.4A | N/A (for generating power, not cooling) | – | ~7W (power generation) | $6 – $9 |

| CP1.0-127-05L | 30 × 30 × 3.2 | 5V | 4.3A | 65°C | 21.5W | ~12W | $2 – $4 |

| TES1-12704 | 30 × 30 × 3.3 | 12V | 4A | 60°C | 48W | ~30W | $2 – $3 |

| ET127-14-11 | 40 × 40 × 4.5 | 15V | 14A | 68°C | 210W | ~130W | $14 – $20 |

| TEC3-12-71-08 | 50 × 50 × 6.0 | 12V | 8A | 70°C | 96W | ~60W | $10 – $15 |

| RC12-6-03 | 30 × 30 × 3.0 | 6V | 3A | 65°C | 18W | ~10W | $2 – $3 |

🧠 Some Quick Notes About This Table:

- ✅ TEC1 series = most common for DIY projects.

- ✅ TEC2 and TEC3 series = better for industrial applications, high voltage or current.

- ✅ TEG series = Thermoelectric Generator, not cooler (opposite of TEC!).

- ✅ Cooling Capacity (Qcmax) = How much heat it can move from cold side to hot side.

- ✅ ΔTmax = The maximum temperature difference you can achieve between sides under no load.

- ✅ Prices vary based on supplier, quantity, and quality (standard, premium, waterproofed, etc).

📈 Price Insights:

- China-based vendors (AliExpress, Alibaba): Lower prices but longer shipping times.

- Local stores / Amazon: Higher prices but faster shipping.

- High-end brands (Laird, Kryotherm): Much higher price (premium-grade industrial TECs).

🏆 Top 5 Recommended Peltier Modules

| Rank | Model | Why Recommended | Best For |

|---|---|---|---|

| ⭐ 1 | TEC1-12706 | Best balance of cost, cooling, and availability | General DIY cooling, small projects |

| ⭐ 2 | TEC1-12715 | Higher cooling power, good for serious projects | Portable coolers, mini-fridge experiments |

| ⭐ 3 | TEC1-12730 | Massive cooling capacity | Industrial projects, high-power coolers |

| ⭐ 4 | TEC2-25408 | Good for 24V systems, decent cooling | Solar-powered coolers, custom HVAC |

| ⭐ 5 | TES1-12704 | Very cheap, compact size | Small gadgets, battery-powered coolers |

#PeltierModule #ThermoelectricCooling #DIYCooling #PeltierEffect #ElectronicsProjects #ThermalManagement #CoolingTechnology #Innovation #EngineeringProjects #EnergyEfficiency

Youre so cool! I dont suppose Ive learn something like this before. So nice to find anyone with some unique ideas on this subject. realy thank you for beginning this up. this web site is something that is needed on the net, someone with a little originality. helpful job for bringing something new to the web!

Hey there! I just wanted to ask if you ever have any problems with hackers? My last blog (wordpress) was hacked and I ended up losing months of hard work due to no back up. Do you have any solutions to stop hackers?

i am using multi layer firewalls